PRECISION MARKING COLOR GRAPHICS

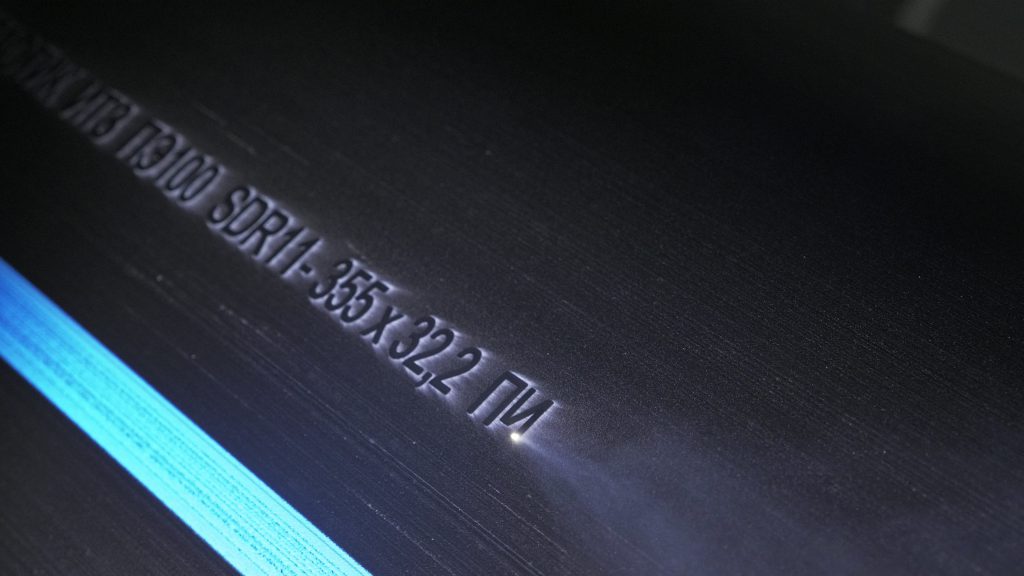

LASER MARKING – Laser marking is an ideal choice for such diverse products as surgical plates, screws, and nails, automotive castings, delicate instrument bases and precision instrument dials. Permanence, fine detail and a perfectly smooth finish are the result. Computerized control allows us to reproduce the finest details of a complex corporate logo or the most diminutive lettering or numbers.

ENGRAVING – Recessed lettering and logos in metal or plastics can be easily routed, either by manual or computer-controlled equipment, into flat or odd shaped surfaces creating virtually wear-proof identification. Lettering may be filled with a contrasting color.

STANDARD DEEP IMAGE PROCESSING – A multistep process to produce products with a one or two color company logo, lettering or other design which penetrates and is protected by the anodized coating. A final sealing step locks the dyes into the pores of the coating, reducing the chance of staining or fading. This unique imaging process creates high quality graphics that are extremely attractive, long wearing and fade resistant over the life of the product. Since the graphics are embedded in the coating, they are not subject to chipping or peeling.

EPOXY INK MARKING – By applying colored inks onto areas such as grooves / slots, color coding can be achieved on products such as medical device instrumentation.

PAD PRINTING – The pad printing process is an alternative to screen printing, particularly for small three-dimensional objects such as dials, knobs, latches, buttons, and golf balls. Pad printing can print both line art and halftoned images on plastics, metals, and painted surfaces with multiple contours.

STENCILING – Precise stenciling of numbers, names, or graphics on almost any surface. Often used for identifying part numbers after chemical film coating or painting.

PART IDENTIFICATION – Ink jet printing important information such as part number, revision and lot onto a desired location on the part.